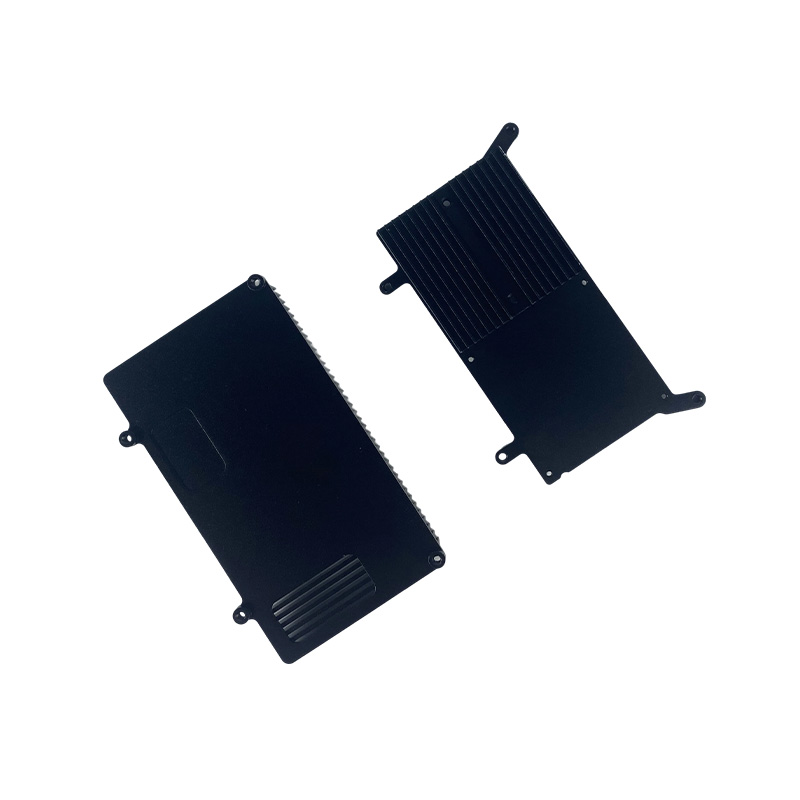

In an era where consumer electronics increasingly prioritize thinness, performance, and reliability, the internal support structure, though invisible, directly determines the overall stability, heat dissipation efficiency, and user experience.

- +86-15999577044

- kelvinqiu@126.com

- Yuantai hardware (3C business department), floor 1, building e, ShangBang science and Innovation Park, dinghou Road, Songgang street, Bao'an District, Shenzhen